|

|

|

|

![]()

Fully-automatic PET Stretch

Blow Moulder >ECON-PET<

Bottle-Volumes: from 0.5 litre up to 2 litres

Output (bph) app.: from 1,000 up to 3,000 bottles per hour

>ECON-PET A 1000< >ECON-PET A 4000<

Machine performance:

* incl. preform selector

* preform transfer to preform transporting system

* heating channel with 5 digital electronic temperature controllers

* non lubricating pneumatic mould closing unit

* robot - unit for inserting thermally processed preforms from chamber into

the mould (2 or 4 cavity mould)

* mech. appliances for removing finished products from the mould

* SIEMENS process control system

* FESTO pneumatic

* DANFOS cooling system

Specifications subject to change without notice !

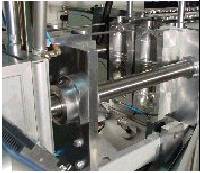

autom. preform take over twin-lane, rotating preform transport

Heating chanel for Preformer with 5 pcs. Quarzlamps Heating-Controll Panel

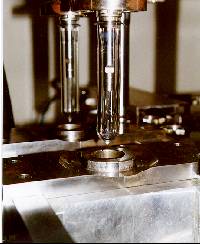

2-cavity mould, pneum. closing system The preforms are deposited into the closed mould

Control panel for machine operation:

mould closing, control of the stretch-piston, timer,

switch for manual-, semiautomatic-, fully automatic operation,

* The preform -

Take-over from the positioned transport trays / preform holder

* The preforms are deposited into the closed bottle mould

* With this system a bending or jamming of the preform is unlikely

* The required stretch-piston can be seen inside the preform

* The whole system of take-over, positioning and closing of the mould operates

pneumatically